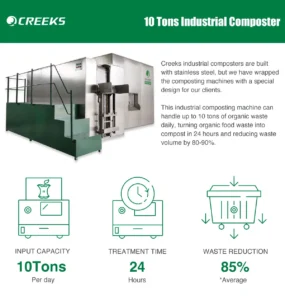

10 Tons Industrial Composter – Large Scale Composting Machine

Sustainable food waste management is an ongoing issue throughout the world. In many cases, food waste is sent straight to landfill where it decomposes and creates harmful greenhouse gases. The practice of disposing of organic waste in landfills also robs our soil of an opportunity to be enriched by the nutrients contained in organic waste.

When it comes to processing large amounts of food waste, facilities are custom-designed and built to suit specific needs and capacity requirements, allowing flexible operation for all situations. The result is a centralized solution, with the ability to incorporate resource recovery.

Creeks industrial composter is an innovative solution that easily converts food waste into a pulp ready for composting and used as an organic fertilizer.

The innovative waste treatment machine effortlessly transforms food waste into recyclable organic fertilizer. Creeks offers a simple, cost-effective way to save money and reduce your environmental footprint. Creeks Industrial Composter is head and shoulders above other organic waste disposal systems.

The industrial composter processes food scraps, meat products, peelings, fish waste, soft bones, and most other leftover foods, as well as compostable cardboard and food packaging, turning everything into nutrient-rich compost in an estimated 24 hours. The installation of the unit at the food waste source eliminates the need for transportation and helps reduce the carbon footprint.

The resulting compost is nutrient-rich, and users can apply it in various horticulture applications at a 1:10 compost-to-soil ratio. Farmers and gardeners can also use it in agriculture as fertilizer to grow a variety of crops.

Industrial Composter Process Principle

Workers load the collected organic waste into the fermentation bin after completing unloading, crushing, solid-liquid separation, and oil-water separation processes. The system maintains high-temperature fermentation with auxiliary heating, keeping the warehouse temperature between 65℃ and 75℃. Continuous gap stirring ensures the warehouse always contains sufficient fresh air for fermentation.

The deodorization system treats the energy released during fermentation and discharges it as gas and water vapor, effectively eliminating odor pollution and preventing secondary contamination from organic waste pollutants. After high-temperature rapid fermentation, the process leaves only about 10% of a non-toxic, harmless organic fertilizer substrate. Farmers can use this fertilizer as an organic soil conditioner to enhance soil structure, improve chemical fertilizer efficiency, enrich the soil, and boost crop yields.

The processing time of the whole fermentation process is about 24 hours, and the reduction rate is more than 90%. There is no need to add other organic matter and nutrient solutions.

Advantages of Using Industrial Composter

- The processing of waste is fast when composting through a machine. It takes fewer hours to complete the procedure, which also implies saving money.

- The composting machine technology generates no secondary pollution.

- Automatic composting machines save operating manpower. One person can easily operate the machine.

- The machine can effectively manage all types of organic waste.

- Built with a stainless steel tank, the machine is durable.

- Creeks composting machine is usually compact and therefore occupies less floor space.

- The machine can convert organic waste into compost.

- Composting benefits the environment by maintaining soil fertility. With the help of compost, soils can retain more water.

- Composting reduces the emission of harmful methane gas into the air.

- Composting serves as a natural fertilizer, thus avoiding the need for any artificial fertilizer for plant growth.

- Using a compost machine also helps reduce transportation costs.

- An increasing number of individuals have now learned about the benefits of organic waste converters. Many organizations are now using compost machines to recycle and convert their waste effectively. The volume reduction efficiency of composting machine technology ranges from 80 to 90%.

Have a question? Ask our experts your questions on the Creeks 10 Tons Industrial Composter.